HMND 01 Humanoid Robot: Product Overview

Technical Specifications

| Specification | Value |

|---|---|

| Model | HMND 01 |

| Height | 175 cm (5’9’’) |

| Weight | 70 kg (154 lbs) |

| Payload | 15 kg (33 lbs) |

| Walking Speed | 1.5 m/s (5.4 km/h) |

| Average Run Time | 4 hours |

| Degrees of Freedom | 41 |

| Actuators | High-torque, high-speed |

| Motion Control | Model-based and learning-based Locomotion Control and Whole-Body Control |

| Power | Information Awaited |

| Material | Information Awaited |

| Operating Temperature | Information Awaited |

Key Features & Benefits

- Highly Efficient Manipulation: Achieves human-level or higher manipulation speeds for complex tasks due to high-torque, high-speed actuators, advanced mechanical design, and end-to-end AI.

- Advanced Motion Control: Robust and precise control systems enable navigation in confined spaces with speed and accuracy.

- Modularity: Hardware and software are designed using a modular concept, allowing customization of upper-body, lower-body, and end-effectors to meet specific customer requirements.

- Reliability & Low TCO: Prioritizes hardware and software stability for industrial-grade robustness, reducing maintenance and offering a low total cost of ownership.

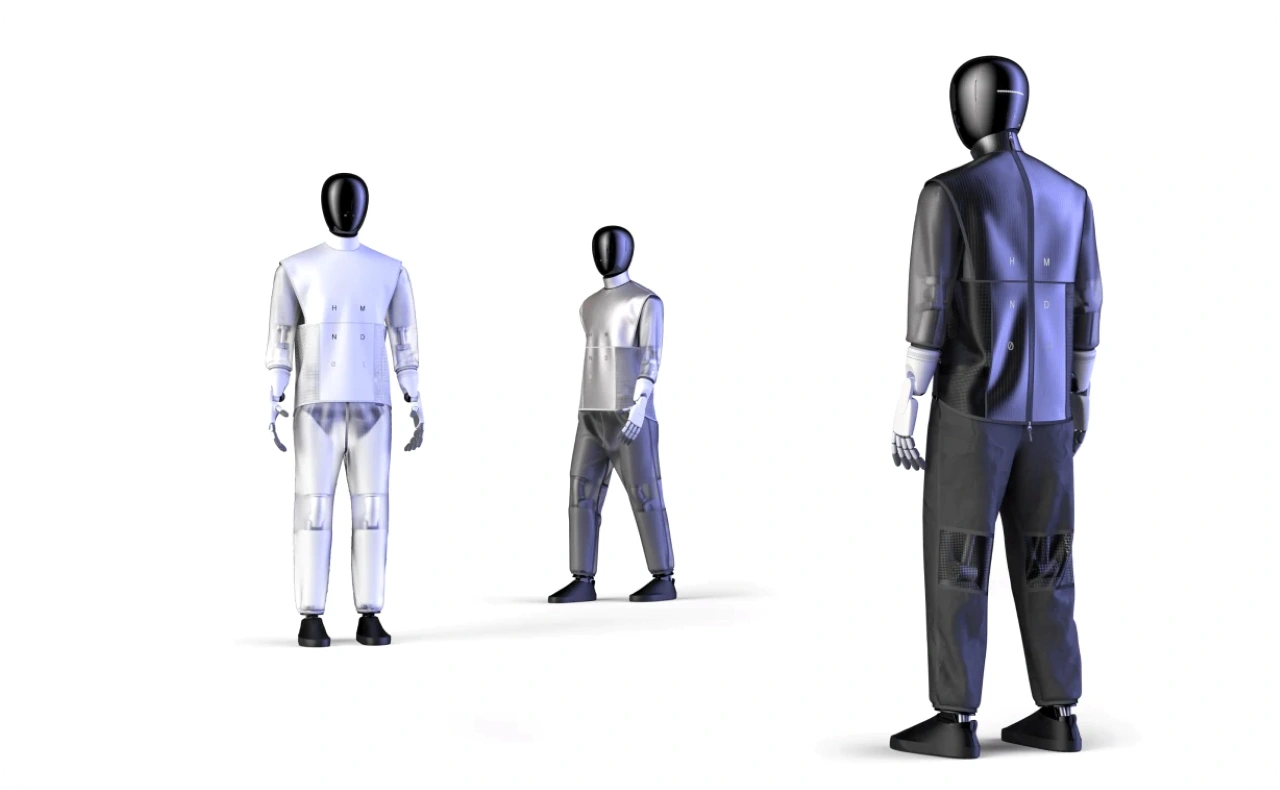

- Functional Customizability: Features exchangeable garments that protect systems and the environment, allowing the robot to adapt to different use cases.

- Seamless Integration: Designed for integration into human-centric environments.

- AI Powered: End-to-end AI for environment perception and object manipulation

Target Applications

The HMND 01 is designed for various industries, focusing on automating labor-intensive operations that current automation technologies cannot effectively address. Its primary focus is on repetitive, dangerous, and mundane tasks. Target users include companies in the following industries:

- Retail: Automating tasks such as stocking shelves, customer service, and inventory management.

- E-commerce: Streamlining order fulfillment processes, including picking, packing, and sorting.

- Third-Party Logistics (3PL): Improving efficiency in warehousing, distribution, and transportation.

- Manufacturing: Automating tasks such as assembly, quality control, and material handling.

- Automotive: Assisting with kitting, part handling, and machine feeding/offbearing in automotive manufacturing facilities.

Use Cases & Scenarios

- Goods Handling: Assists with transporting and moving heavy items in logistics centers, warehouses, and retail facilities.

- Picking & Packing: Enhances efficiency in selecting and packing goods for shipping in order fulfillment centers and e-commerce warehouses.

- Kitting & Part Handling for Manufacturing: Supports kitting processes, part handling, and machine feeding/offbearing in automotive, electronics, and other manufacturing environments.

- Visual Inspections: Performs visual inspections in industrial settings, ensuring product quality and compliance.

- Warehouse Automation: Automates material moving operations within warehouses, including loading and unloading trucks, moving inventory, and fulfilling orders.

- Machine Tending: Operates machinery by loading, unloading, and monitoring the process.

Unique Selling Points

- Human-Level Dexterity: Mimics human movements, enabling it to perform complex tasks that require fine motor skills.

- Adaptive Learning: Can learn and adapt to new tasks and environments through AI and machine learning algorithms.

- Seamless Integration: Designed to integrate into existing human-centric environments without significant workspace redesign.

- Cost-Effectiveness: Modular design and low TCO make it a cost-effective solution for automating labor-intensive operations.

- High Performance: Achieves human-level or higher manipulation speeds, increasing efficiency and productivity.

Industries Utilized

- Manufacturing

- Logistics

- Warehousing

- Retail

- E-commerce

- Automotive

Competitive Advantages

- Modularity and Customization: The modular design enables customers to tailor the robot to their specific needs, reducing costs by incorporating only essential hardware and software features.

- AI-Powered Dexterity: Achieves human-level or higher manipulation speeds for complex tasks, surpassing traditional industrial robots in dexterity.

- Low Total Cost of Ownership (TCO): Prioritizing hardware and software stability results in industrial-grade robustness, reducing maintenance needs and overall operating costs.

- Seamless Integration: The Humanoid form factor allows seamless integration with existing infrastructure designed for humans.

More Information

The HMND 01 integrates cutting-edge AI for efficient loco-manipulation and is available for both autonomous and teleoperated deployment. Humanoid aims to develop wheeled and bipedal alpha prototypes in 2025, signaling ongoing innovation and development in the humanoid robotics field.

Other Robots of Humanoid

- Information Awaited

Pricing and Availability

- Pricing: No information for sale at this time

- Brochure: Information Awaited

- Demo Request: https://thehumanoid.ai/product

- Technical Whitepaper: Information Awaited

Competitor Products

- Tesla Optimus: An AI-powered humanoid robot designed for a range of tasks, including manufacturing and household chores. It is expected to be priced around $25,000 to $30,000.

- Figure AI Humanoid: A general-purpose humanoid robot designed for various tasks in logistics, warehousing, and manufacturing.

- Apptronik Apollo: Designed for logistics, warehousing, and manufacturing.

Contact & Resources

- Contact: [email protected] Key Links:

- About Us: https://thehumanoid.ai/about-us

- Products: https://thehumanoid.ai/product

- Careers: https://thehumanoid.ai/careers

- News: https://thehumanoid.ai/newsroom

- Privacy Policy: https://thehumanoid.ai/privacy-policy