Agility Robotics Humanoid Robot: Product Overview

Technical Specifications

| Specification | Value |

|---|---|

| Model | Digit |

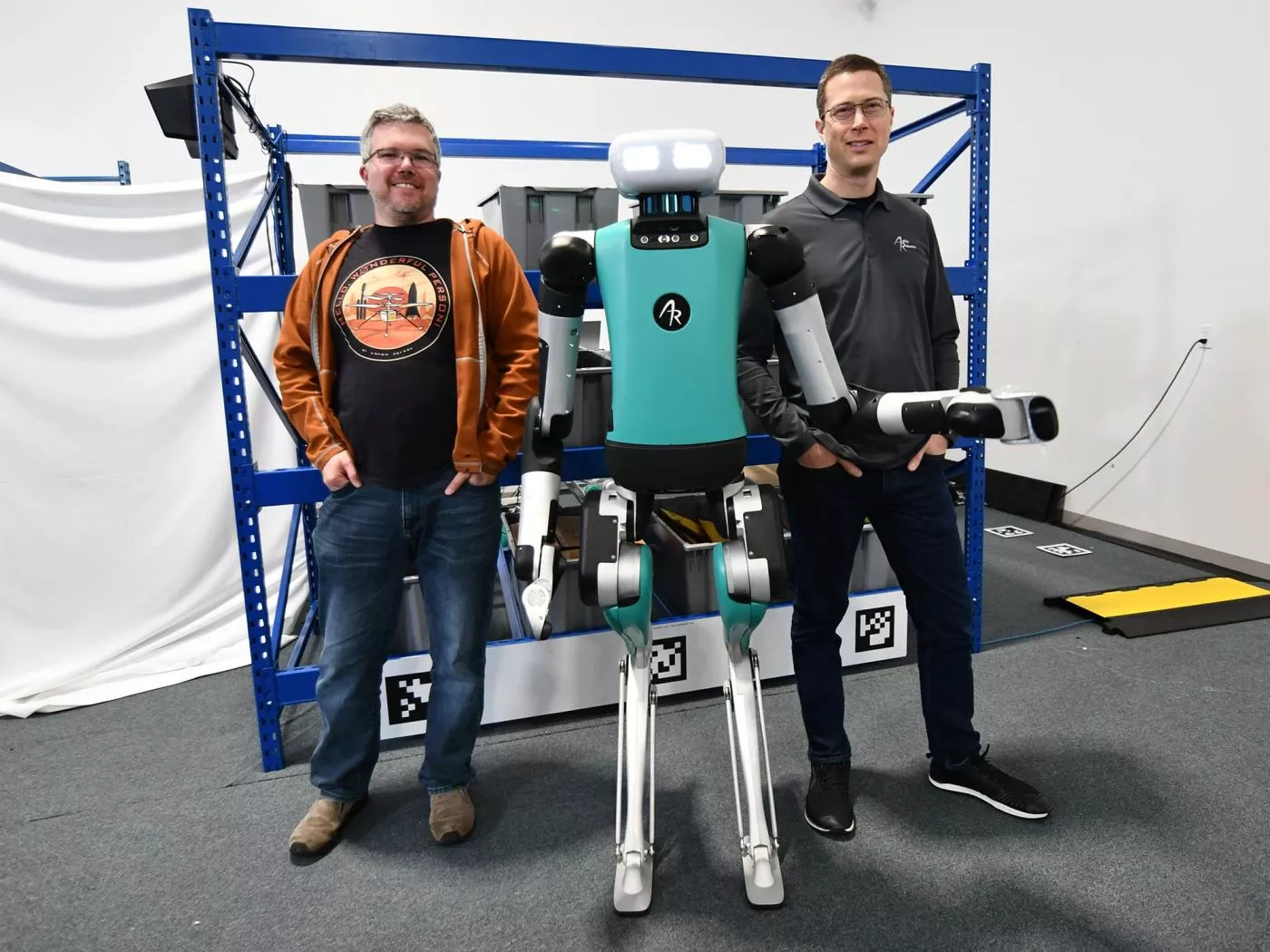

| Dimensions (Height) | 5' 9" (approx. 1.75 m) |

| Weight | Approx. 37 kg |

| Payload | 35 lbs (approx. 16 kg) |

| Speed (Walking) | Approx. 1.5 m/s (similar to average human walking speed) |

| Sensors | LiDAR, Multiple Camera Arrays, Integrated Perception System |

| Compute | Onboard AI-driven computation |

| Software Platform | Agility Arc™ Cloud Platform Integration |

| Operational Reach | Floor to 5' 6" (approx. 1.68 m) |

| Locomotion | Bipedal with unique leg design for agility |

| End Effectors | Customizable (specialized options for tasks like tote handling) |

| Power | Electric with Autonomous Docking & Charging Capability |

| Safety Features | Integrated E-Stop, designed to meet industry safety standards |

| Other Specs | Maintenance ports on back panel, Capable of navigating complex terrain (incl. stairs) |

Key Features & Benefits (of Digit)

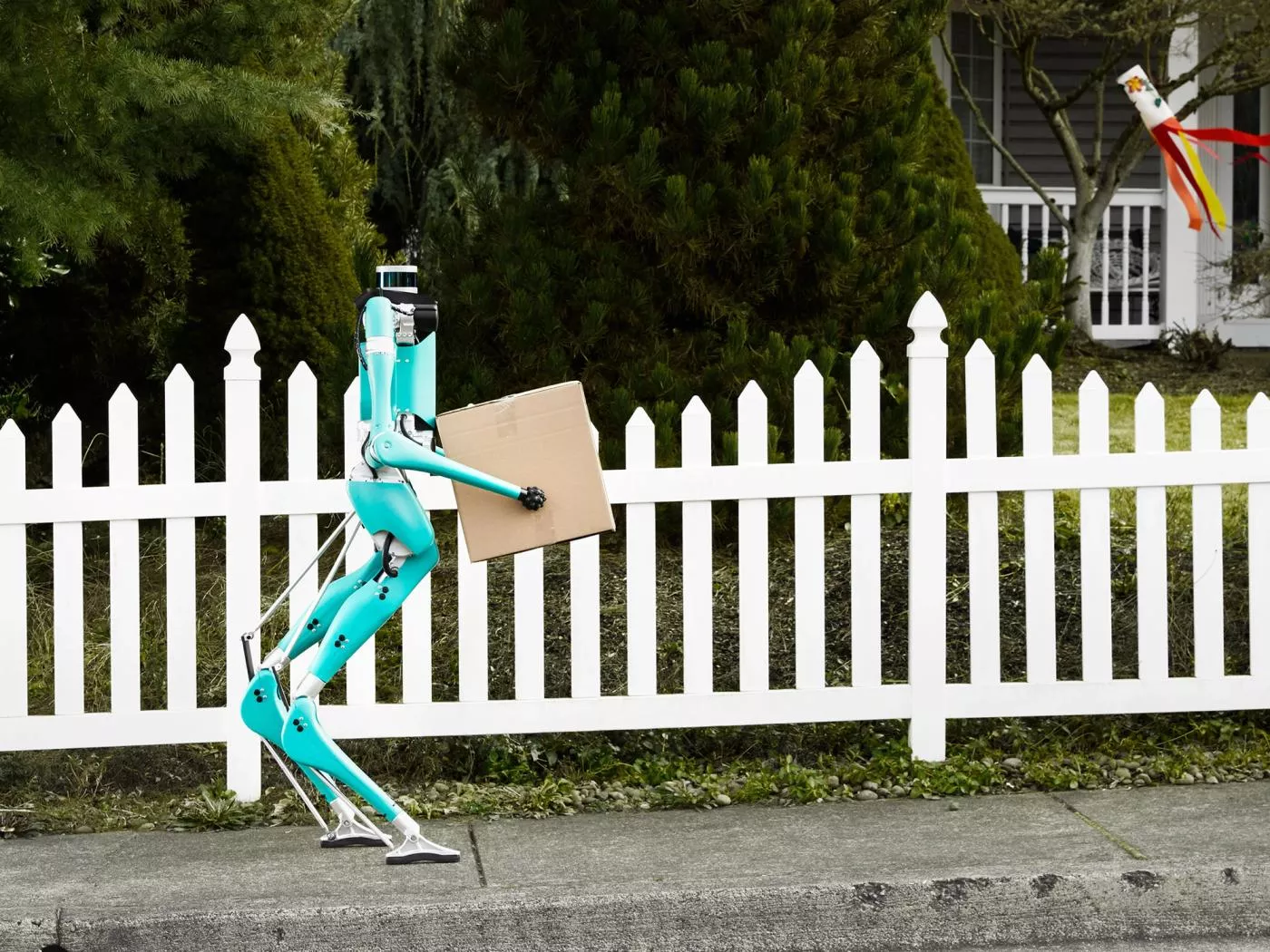

- Human-Centric Design: Operates effectively in environments built for people, including navigating stairs, ramps, and tight spaces without facility retrofitting.

- Seamless Workflow Integration: Designed to integrate into existing warehouse and manufacturing operations with minimal disruption, connecting existing automation islands.

- Autonomous Operation: Utilizes advanced AI and perception (Embodied AI) to navigate complex environments, identify objects, and perform manipulation tasks like grasping and carrying totes autonomously.

- Safety as a Priority: Built and deployed according to rigorous safety standards, capable of working alongside human employees safely due to its controlled speed and awareness.

- Task Flexibility & Adaptability: Capable of performing a growing range of material handling tasks (via the Skill Library) and adapting to changing operational needs and demand fluctuations.

- Agility Arc™ Ecosystem: Managed via a cloud-based platform for deployment, task management, system integration (WMS/WES/MES), monitoring, and fleet coordination.

- Advanced Bipedal Locomotion: Leverages decades of research for efficient, stable, and agile movement across various floor types and terrains found in industrial settings.

- Optimized Manipulation: Equipped with perception and customizable end effectors specifically designed for efficiently handling common logistics items like totes.

- Scalable Deployment: Offered via Robot-as-a-Service (RaaS) or Capital Expenditure (CapEx) models, supported by large-scale US-based manufacturing (RoboFab).

Target Applications (for Digit)

Digit is engineered for bulk material handling tasks within dynamic industrial environments. Its primary applications focus on automating repetitive, physically demanding, or potentially hazardous jobs where human labor is scarce or better utilized elsewhere.

- Warehouse Automation: Handling tote movement, replenishment, consolidation, loading/unloading Autonomous Mobile Robots (AMRs) and conveyor systems.

- Manufacturing Support: Transporting parts and materials between workstations, supporting line-side logistics.

- Distribution Center Operations: Optimizing sorting, palletizing/depalletizing totes, and managing material flow in complex layouts.

- Logistics & Supply Chain: Bridging gaps in automated workflows, enhancing overall throughput and efficiency.

Use Cases & Scenarios (with Digit)

Digit excels in scenarios requiring mobility and manipulation within existing human-centric infrastructure:

- Tote Loading & Unloading: Autonomously picking up totes from and placing them onto AMRs, conveyors, shelves, Goods-to-Person (G2P) stations, and sortation systems. Intelligently handles exceptions, like stacking totes nearby if a downstream system is paused.

- Tote Recycling & Management: Efficiently stacking, destacking, and nesting empty totes to optimize space and ensure availability for operations.

- Tote Palletizing & Depalletizing: Building or breaking down pallet loads of totes, interacting with conveyors, carts, or other automation systems.

- Connecting Automation Islands: Acting as a mobile link between different fixed or mobile automation systems within a facility.

- Working Near Humans: Performing tasks in areas shared with human workers, adhering to safety protocols and predictable movement patterns.

Unique Selling Points (of the Digit Solution)

The Digit solution distinguishes itself in the growing field of humanoid robotics through several key factors:

- Proven Commercial Deployment: Recognized as the world's first commercially deployed humanoid robot (Digit), actively working in customer facilities like Amazon and GXO/Spanx.

- Purpose-Built for Logistics: Digit is specifically designed and optimized for the physical demands and common tasks (especially tote handling) found in warehouses and distribution centers.

- Human-Environment Native: Digit excels at navigating existing infrastructure designed for humans, minimizing the need for costly facility modifications.

- Integrated Hardware & Software Solution: Offers a complete package with the Digit robot and the Agility Arc™ cloud platform for seamless management and integration.

- US-Based Scalable Manufacturing: Operates RoboFab, the first US-based factory dedicated to mass-producing humanoid robots, enabling large-scale deployments.

- Embodied AI Approach: Strategically applies AI within Digit's control systems to accelerate skill learning and adaptability for real-world tasks.

Industries Utilized (by Digit)

Digit is primarily being adopted in industries facing significant labor challenges and high volumes of material movement:

- Logistics & Supply Chain

- Warehousing & Distribution

- Third-Party Logistics (3PL)

- Manufacturing

- Retail & eCommerce Fulfillment

Competitive Advantages (of the Digit Solution)

Compared to traditional automation and other robotic solutions, the Digit solution offers distinct advantages:

- Infrastructure Flexibility: Requires minimal changes to existing facility layouts, unlike fixed conveyor systems or large AGVs.

- Task Versatility: Digit can perform a variety of different material handling tasks with software updates (Skill Library), offering greater adaptability than single-purpose robots.

- Human-Scale Accessibility: Digit operates in narrow aisles, navigates stairs, and reaches locations inaccessible to forklifts or larger robotic platforms.

- Scalability & ROI: RaaS and CapEx options allow flexible adoption, while high-volume manufacturing supports large fleet deployments, aiming for strong ROI by addressing labor costs and boosting throughput.

- Integrated Management Platform: Agility Arc™ provides a unified interface for managing, integrating, and optimizing robot operations across potentially large fleets.

- Focus on Practical Tasks: Prioritizes solving immediate, high-impact problems in logistics rather than aiming for general-purpose human replacement initially.

More Information (About Digit and Agility Robotics)

Digit represents the culmination of decades of academic research into dynamic bipedal locomotion, originating from Oregon State University. Agility Robotics leverages this deep expertise, combining robust mechanical design with sophisticated "Embodied AI." This approach involves strategically integrating AI techniques within the robot's complex control hierarchy, enabling faster learning of new skills and more adaptable real-world performance. The core design philosophy centers on creating a practical, safe, and efficient automation tool (Digit) that works within human environments to augment the workforce, tackling the 'dull, dirty, and dangerous' tasks and addressing critical labor shortages in key industries like logistics and manufacturing. The goal is not just to build a walking robot, but a useful tool that delivers tangible value to businesses today.

Other Robots of Agility Robotics

- Cassie: An earlier bipedal robot platform developed at OSU and commercialized by Agility Robotics. Primarily used for research, Cassie lacked a torso and arms but demonstrated advanced dynamic locomotion, setting a Guinness World Record for the fastest 100m dash by a bipedal robot.

Pricing and Availability (for Digit)

- Pricing: Robot as a Service (RaaS) and Capital Expenditure (CapEx) options available. Contact Agility Robotics for specific pricing details.

- Demo Request: Request Information / Demo

- Technical Whitepaper: Available Resources

Competitor Products (to Digit)

The field of humanoid robotics for industrial applications is rapidly evolving. Key competitors and alternative platforms include:

- Figure 01 / Figure 02 (Figure AI): Humanoid robots with a 20kg payload, 5-hour runtime, electric power, targeting manufacturing, logistics, warehousing, and retail. Focus on AI and dexterity.

- Walker S (UBTECH Robotics): 1.7m tall industrial humanoid robot designed for manufacturing environments, featuring force compliance, advanced perception, and LLM integration.

- Optimus (Tesla): General-purpose humanoid robot under development by Tesla, aiming for broad applicability in manufacturing and beyond. Still largely in R&D phase compared to Digit's commercial deployment.

- Apollo (Apptronik): Humanoid robot designed for logistics, manufacturing, and potentially other industries, focusing on safe human-robot interaction and utility.

- Phoenix (Sanctuary AI): Humanoid robot emphasizing human-like intelligence and fine motor skills, targeting a wide range of tasks through AI-driven control.

- NEO (1X Technologies): Bipedal humanoid robot following their wheeled EVE platform, targeting logistics, retail, and security applications.